Anyone who is familiar with the process of dry ice blasting will be happy to use the effective method and recommend it to others at any time. Without effort and completely environmentally friendly, you can use the powerful method for a variety of purposes. The mobile application of the cleaning is simply unbeatable. You can use the dry ice method almost everywhere where you have a power connection.

Using the cold effect to make the dirt brittle

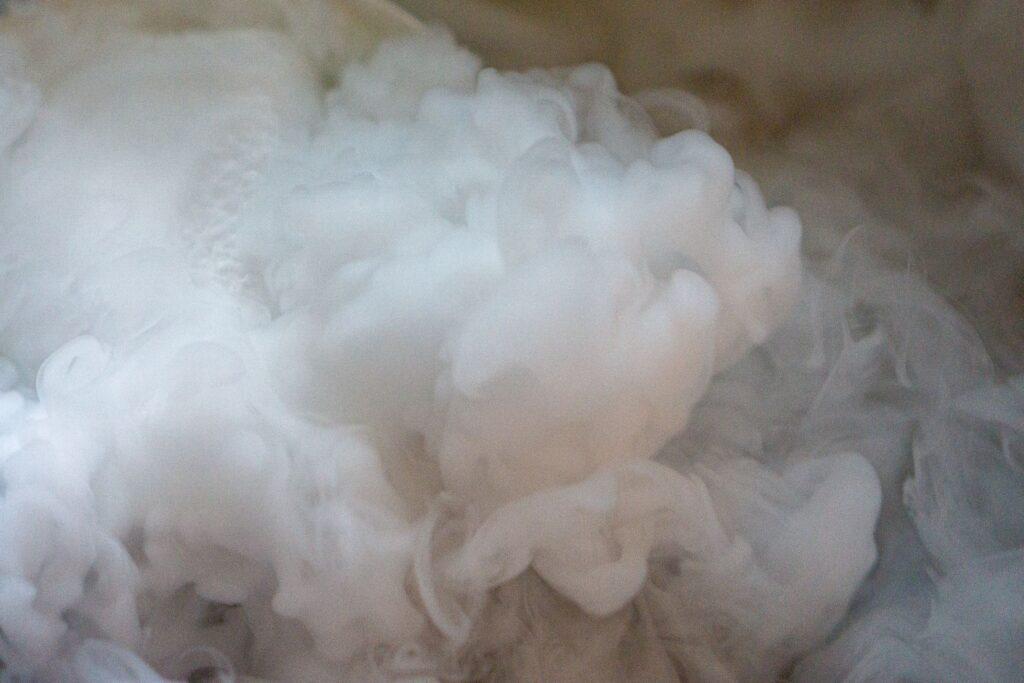

In dry ice blasting, as the process is called in English, the low temperatures of dry ice are very effective in embrittling dirt or adhering materials that are stuck to the surface to be cleaned. The brittleness results in a better detachment of the dirt, which can be easily removed by the pellets hitting with high pressure. The temperature of the dry ice of about -78 degrees leads to a hardening of the structure of almost all materials, there is then no more sticking or smearing of materials.

Kinetic effect for clean surfaces

The kinetic effect caused by the very high speed of the dry ice pellets when they hit the surface of the material to be cleaned also contributes to effective cleaning. The particles of contamination are powerfully removed. For this purpose, dry ice is passed through special nozzles that cause the pellets to accelerate to supersonic speed. The high force of the impact on the material leaves no chance for contamination.

Dry ice expands

Another enormous force is in the sublimation of the dry ice particles. These expand extremely when they hit the surface of a material. When they get between the dirt particles and the material, they literally blast off the layer of dirt.

Advantages of dry ice blasting

The advantages of dry ice blasting lie primarily in its clean application. No water is contaminated, there are no waste products and because the dry ice converts to carbon dioxide during application, no residues from the cleaning agent are to be expected. Since no chemical products are needed for the process either, one can speak of a very environmentally friendly method of cleaning. Dry ice blasting is suitable for many applications where conventional cleaning methods fail.

Where you want to remove oily, greasy, sticky residues from surfaces, you can use the dry ice process. Since you can use mobile equipment for the job, the effective cleaning method is gaining a lot of momentum in industries and trades. It replaces other processes that cause waste or contaminate water. This development can only be endorsed because it means less water is wasted and the environment is no longer polluted with chemical products and their decay particles. The clean and above all gentle cleaning of surfaces lends itself to many uses.